|

| |

|

Precision CNC Tube Measuring and Bending |

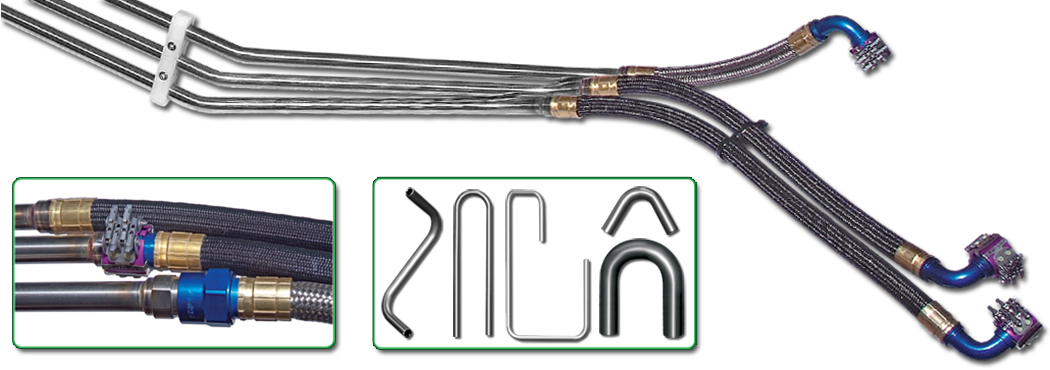

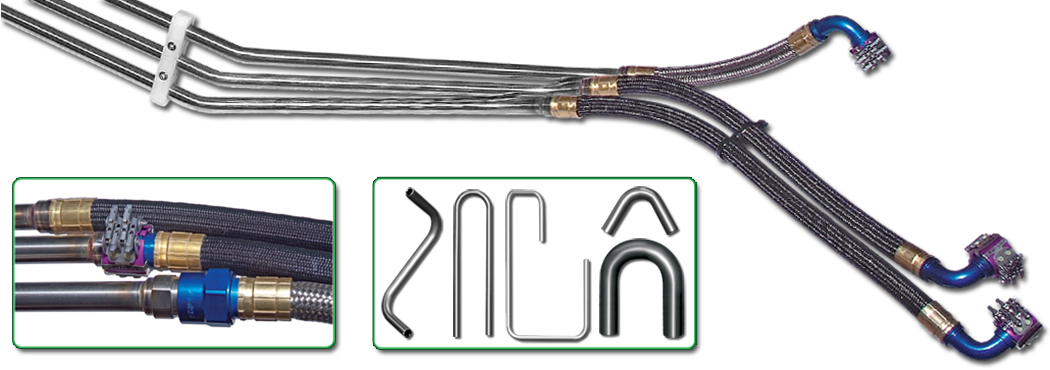

| At Brown & Miller Racing Solutions we are at the forefront of technology in lightweight racing hose and fittings and are committed to servicing professional race teams and engine builders world wide. Now we have installed the very latest in CNC tube bending and measuring equipment to further complement our lightweight PROGold hose and fittings range. This includes: |

| |

| • State of the Art Bending Equipment |

| • Size Range of 1/8" to 2" |

| • No Quantity Requirements |

| • Minimum Turn Around Time |

| • Materials - Aluminum, Steel, Stainless Steel, Titanium, etc. |

| • High Degree of Accuracy and Repeatability |

|

| |

| • State of the Art Multi-Axis Measuring Equipment |

| • Manufacture from Drawings |

| • Reverse Engineering from Existing Tube and Mock-Up Parts |

| • Capable of Precision QC for Exact Fit Requirements |

|

| |

|

|

Precision CNC Tube Measuring and Bending |

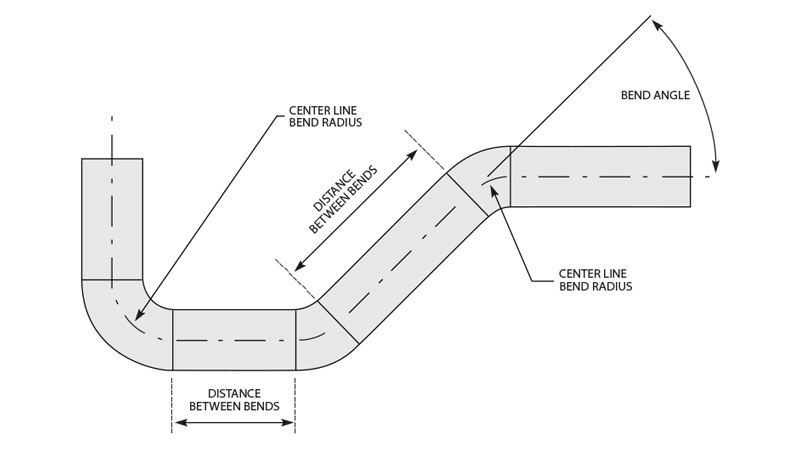

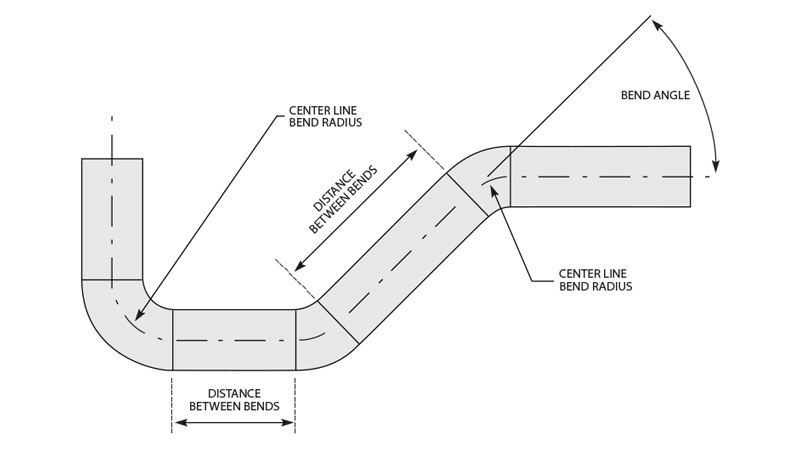

The following information catalogs the current bend tools that are available. This list is constantly being added to, so check with us if your specific requirement does not appear to be listed.

The "Clamp Length" is the minimum distance between bends that can be achieved (See illustration below). This figure, plus a small clearance allowance of 1/8", should be taken into account when designing complex compound tube bends. In any specific compound tube bend design only one Center Line Bend Radius should be selected.

Bend Angle is defined as the actual angle the tube is bent through.  |

| |

|

| |

|

| |

Brown & Miller Racing Solutions is able to interpolate all common CAD and 3D model data directly into our bending equipment. We can also work with X, Y, Z co-ordinates, mock up parts or existing patterns. (Also see charts next page). |

| |

|

|

| Back to Top |

| |

| |

|

| |

|

| |

|

| |

| Copyright © 2018. Brown & Miller Racing Solutions. All rights reserved. |